- The lockstitch machine is a versatile tool used in various sewing projects, from clothing and accessories to home decor and upholstery. It is suitable for sewing different types of fabrics, from delicate silk to heavy denim, making it a popular choice among both professional sewers and hobbyists.

In conclusion, auto sewing represents a groundbreaking shift in the textile industry, offering notable benefits such as increased efficiency, consistency, and cost savings. While challenges exist, including workforce displacement and initial investment costs, the potential for innovation and sustainability is immense. As the industry adapts and evolves, the collaboration between technology and human skill will ultimately forge a path toward a more efficient and sustainable textile production landscape. Embracing this change could be the key for companies to thrive in a rapidly changing market.

The origins of CNC technology can be traced back to the 1940s and 1950s, when engineers began experimenting with automated machine tools. However, it wasn't until the 1980s and 1990s that CNC technology made its way into the sewing industry. The initial machines were bulky and limited in functionality, but as technology progressed, they became more compact and versatile.

Recommended Heavy-Duty Sewing Machines

The impact of automatic machine sewing extends beyond the production line; it also reshapes the workforce dynamics within the industry. While automation may lead to a reduction in the number of manual sewing jobs, it simultaneously creates new opportunities in machine operation, programming, and maintenance. Workers are required to adapt to these changes by acquiring new skills related to operating sophisticated machinery and understanding digital design software. As a consequence, the industry sees a shift toward a more technologically savvy workforce, fostering a culture of continuous learning and adaptation.

- Type of Material Different machines are tailored for specific materials. Understanding the composition of the bags being used is essential for choosing the appropriate seaming technique.

It's essential to consider your specific needs and budget when evaluating pattern sewing machine prices. Investing in a high-quality machine can lead to long-term savings by reducing maintenance costs and increasing production efficiency.

Understanding Handheld Sewing Machines

Industrial Sewing Machines: These are the top performers. They stitch fast, much faster than heavy-duty machines, and can keep going without getting too hot.

Key Features

In the ever-evolving world of garment manufacturing, understanding operational costs is crucial for maintaining competitiveness and profitability. Among the myriad factors that contribute to these costs, the overlock machine rate plays a significant role. This article delves into what overlock machine rates are, their importance in the textile industry, and how manufacturers can optimize their costs.

Features and Benefits

While overlockers are often associated with commercial sewing, they are also incredibly beneficial for home sewers. An overlocker can elevate a hobbyist’s projects, providing a professional finish that significantly improves the appearance of homemade garments. Many modern overlockers come equipped with user-friendly features that make them accessible to sewists of all skill levels, including color-coded threading guides and adjustable stitch settings.

Conclusion

Investing in a zig zag industrial sewing machine can be a game-changer for seamstresses, tailors, and businesses involved in textile production. Its versatility, durability, and ability to produce high-quality stitches make it a smart choice for anyone looking to elevate their sewing capabilities. By considering your needs and exploring available options, you can find the perfect zig zag sewing machine that will serve you for years to come. Whether you are a seasoned professional or a passionate hobbyist, the right industrial sewing machine can bring your creative visions to life with speed and precision.

Leather is a robust and durable material, and it requires special handling compared to standard fabrics. Its thickness, texture, and weight can vary significantly, which means that not all sewing machines can handle it efficiently. Leather often features a natural grain that not only adds to its aesthetic appeal but also presents challenges when sewing, such as the risk of slipping or uneven seams. Therefore, selecting a sewing machine specifically designed for leather is crucial.

Several brands are well-regarded in the world of heavy-duty sewing. Machines like the Sailrite Fabricator, Juki TL2010Q, and Brother PQ1500SL are often recommended for upholstery due to their strength and functionality. Each of these models offers various features that make them suitable for sewing through multiple layers of tough fabrics.

One of the defining features of heavy-duty sewing machines is their enhanced stitch capability. Many models come equipped with a wider variety of stitch options, including straight stitches, zigzag stitches, and decorative stitches. This versatility allows you to utilize the machine for a range of projects, from basic clothing repairs to intricate quilting and crafting. Additionally, a heavy-duty machine often includes features such as adjustable presser foot pressure and a higher sewing speed, enhancing both efficiency and precision.

3. Adjustable Height Look for tables that offer adjustable height settings. This feature allows you to work at a comfortable level, reducing strain on your back and neck during long sewing sessions.

The Benefits and Features of Multi Needle Quilting Machines

Additionally, chain stitch seams are known for their strength. Unlike other stitching methods, chain stitches can bear significant tension without breaking, making them ideal for areas of garments subject to stress, such as armholes and seat seams. This durability not only enhances the lifespan of the garments but also reduces returns and complaints related to seam failures, which is beneficial for manufacturers.

2. Improved Results Achieving the desired finish is critical in sewing. Strong sewing machine needles can create neater stitches and minimize fabric puckering or damage, resulting in a polished final product. When working with heavy fabrics, using the right needle ensures that the stitching holds up under stress, providing both functionality and aesthetics.

strong sewing machine needles

Conclusion

The Importance of Automatic Bag Closer Machines in Modern Packaging

- Thread Selection Use high-quality thread to avoid breakage and ensure smooth stitching. Different fabrics may require specific thread types; for instance, polyester threads are often recommended for added stretch.

Decorative Stitches

1. Powerful Motor One of the most significant advantages of a heavy-duty quilting machine is its powerful motor, which can sew through multiple layers of fabric, batting, and even denim. This is essential for quilting, where it’s common to work with several layers at once.

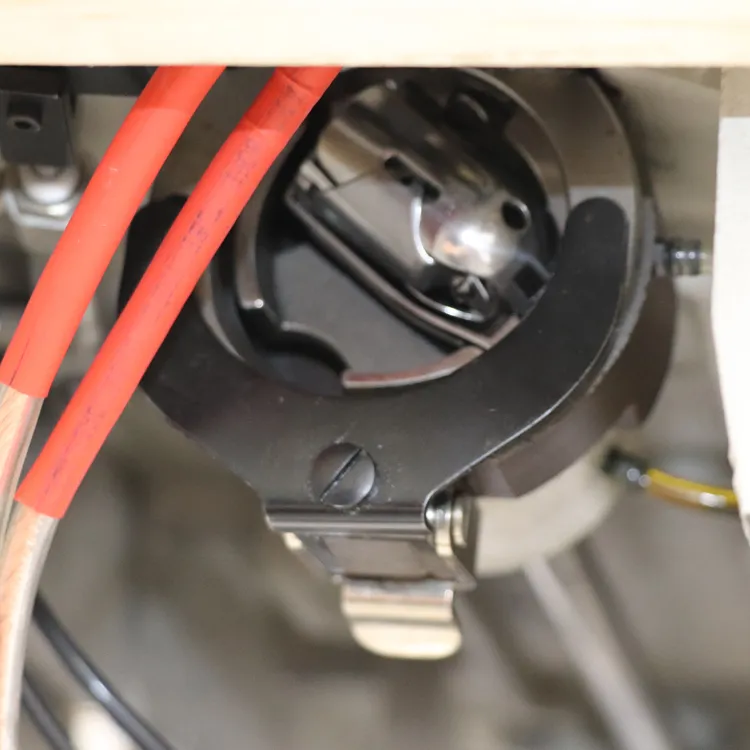

What is Lock Stitch?

In addition to speed, automatic quilting machines also offer a level of precision that is unmatched by hand quilting. These machines are programmed to follow a specific pattern or design, ensuring that each stitch is the exact same length and spacing. This level of consistency is difficult to achieve by hand and results in a professional-looking quilt every time. Whether quilting a simple block pattern or a more complex design, automatic quilting machines can handle it all with precision and accuracy.

automatic quilting machine

Benefits for Users

In the world of industrial packaging, the way materials are secured and protected plays a crucial role in ensuring product integrity, safety, and efficiency during storage and transportation. One of the key innovations in this field is the use of jumbo bag lock stitch technology, which has become increasingly popular for large-scale packaging operations. This technique offers numerous benefits that enhance the performance and reliability of jumbo bags, commonly used for bulk materials such as grains, fertilizers, chemicals, and other industrial products.